How does a ball valve work

Understanding the mechanics of a ball valve is essential for anyone involved in plumbing, industrial applications, or even simple DIY projects. Ball valves are a crucial component in controlling the flow of liquids and gases through a system. In this article, we will delve into the workings of a ball valve, explore the different types available, and discuss their various applications.

What is a Ball Valve?

A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of a fluid or gas. When the ball's hole is aligned with the flow, the valve is open, and when the ball is rotated 90 degrees by the valve handle, the flow is blocked. This simple mechanism makes ball valves highly effective and reliable.

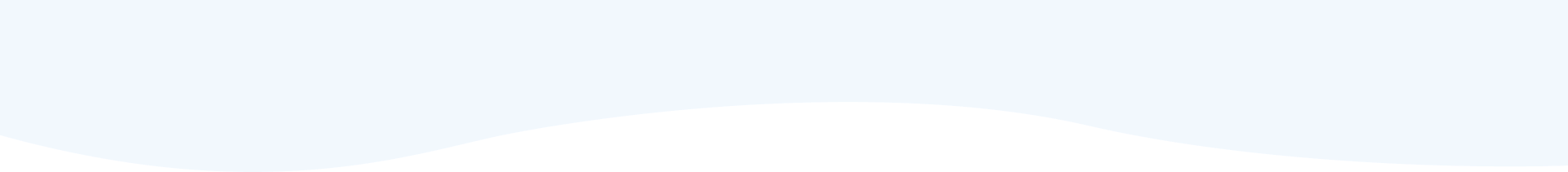

Components of a Ball Valve

Ball valves are made up of several key components:

- Valve Body: The main structure that holds the valve mechanism together.

- Ball: The sphere inside the valve that controls flow.

- Seats: Soft rings that provide a seal between the ball and the valve body.

- Stem: Connects the ball to the external control handle.

- Handle or Lever: Used to manually turn the ball inside the valve.

How Does a Ball Valve Work?

The operation of a ball valve is straightforward. The valve is controlled by rotating the handle or lever, which in turn rotates the ball.

Open Position

When the handle is parallel to the pipe, the ball's hole is aligned with the flow path, allowing fluid or gas to pass through. This is known as the open position. The design ensures minimal resistance and pressure drop when the valve is open.

Closed Position

Rotating the handle 90 degrees moves the ball so that the solid side of the sphere blocks the flow path. This is the closed position, which stops the flow completely. The simplicity of this mechanism provides a quick and reliable way to start or stop flow.

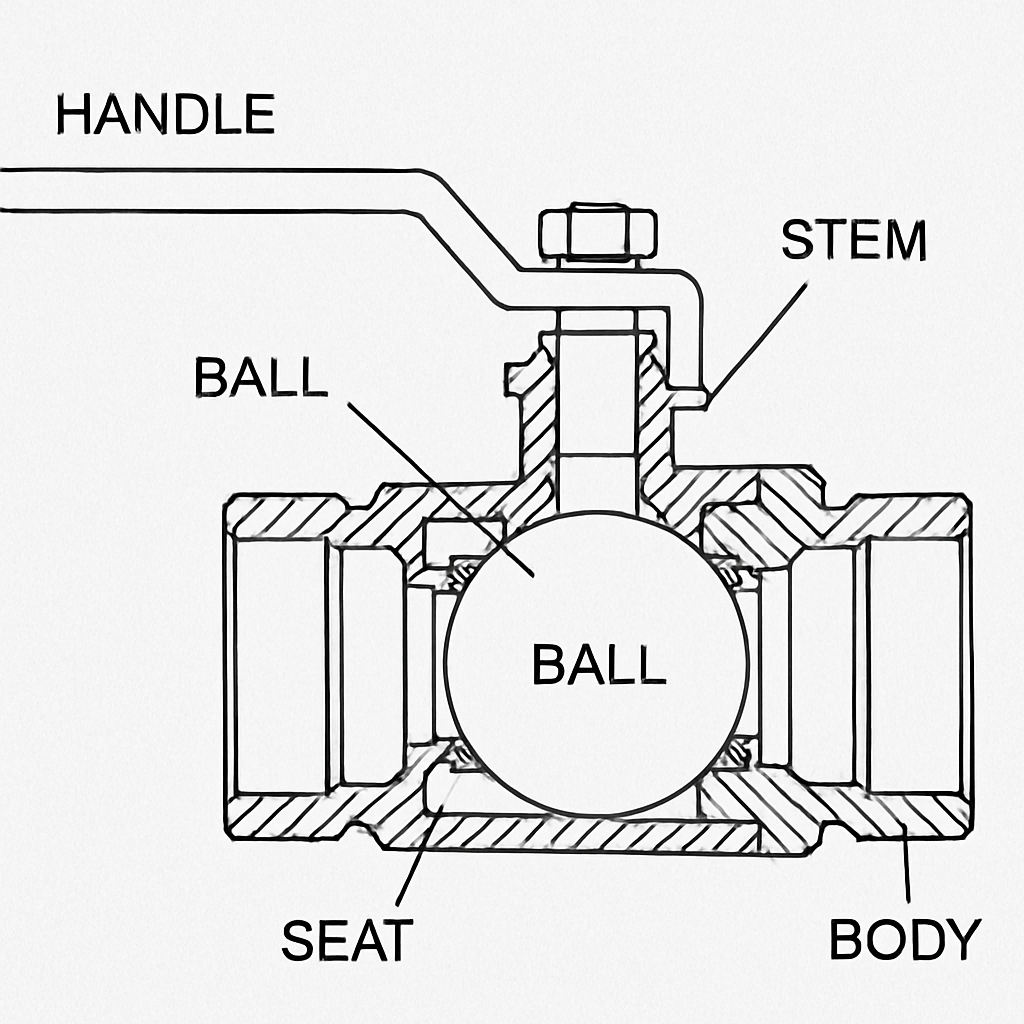

Types of Ball Valves

Ball valves come in various types, each designed for specific applications and operational conditions.

Floating Ball Valve

In a floating ball valve, the ball is held in place by the valve seats but is not fixed by a trunnion. This allows the ball to float slightly downstream, which enhances the sealing capabilities of the valve under pressure.

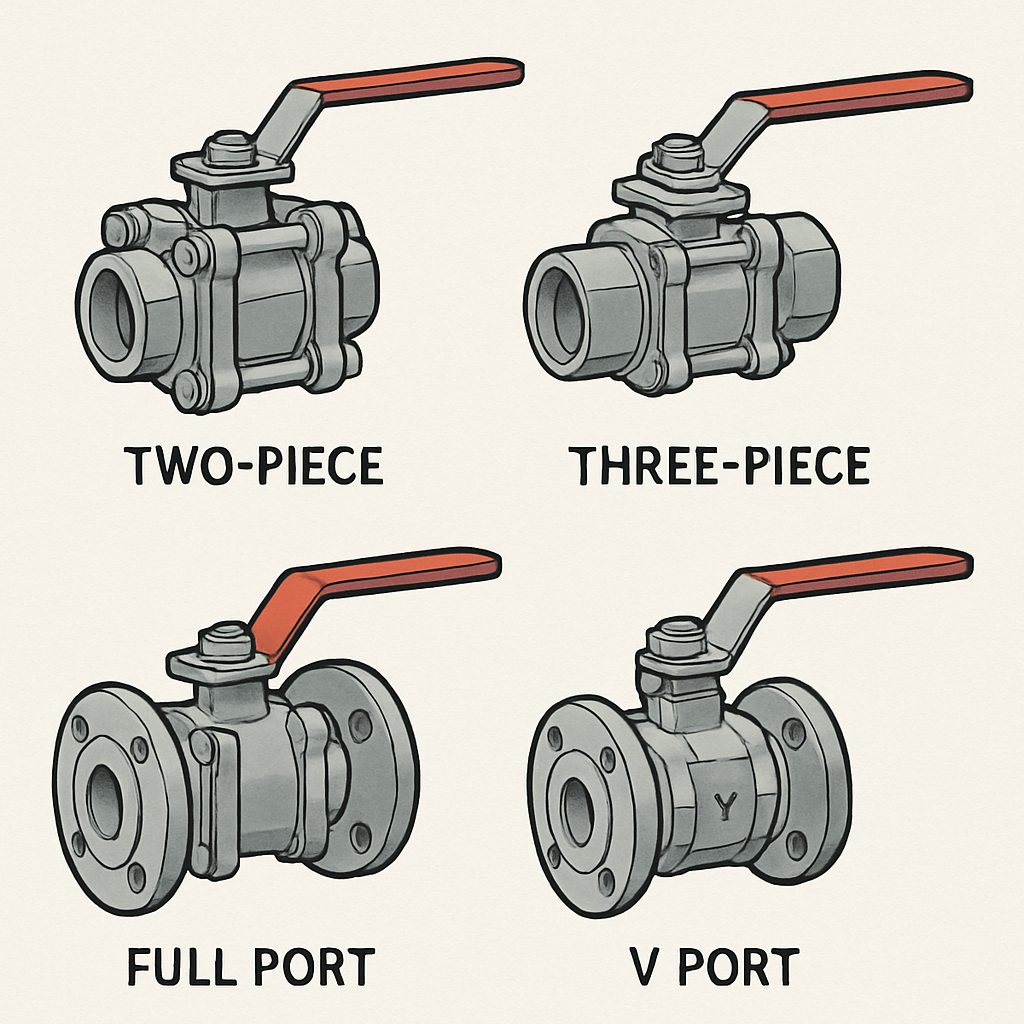

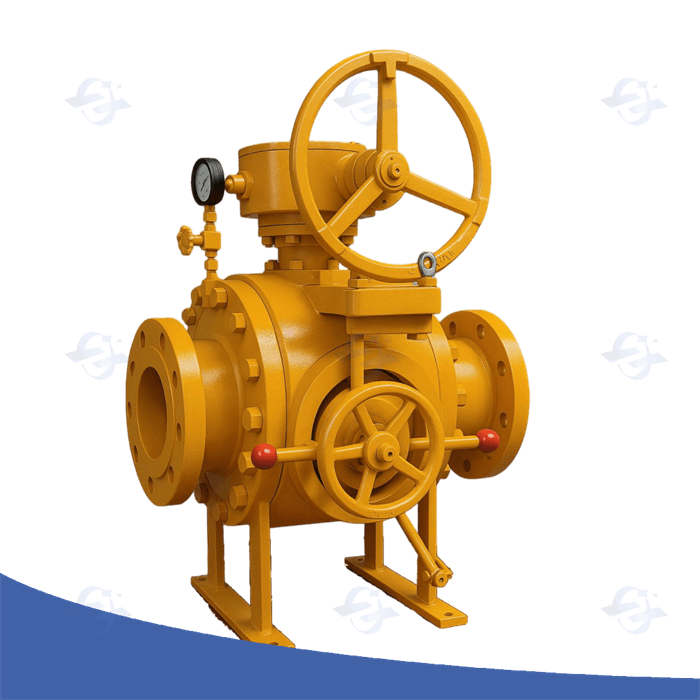

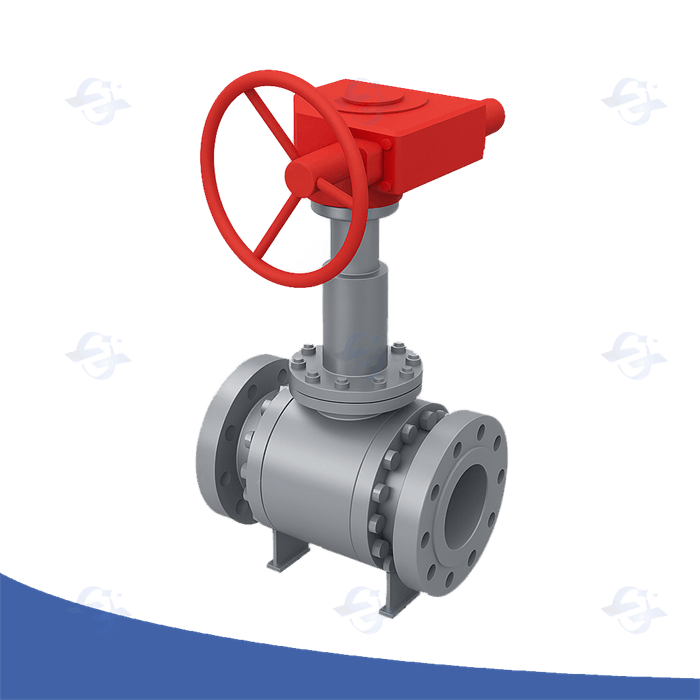

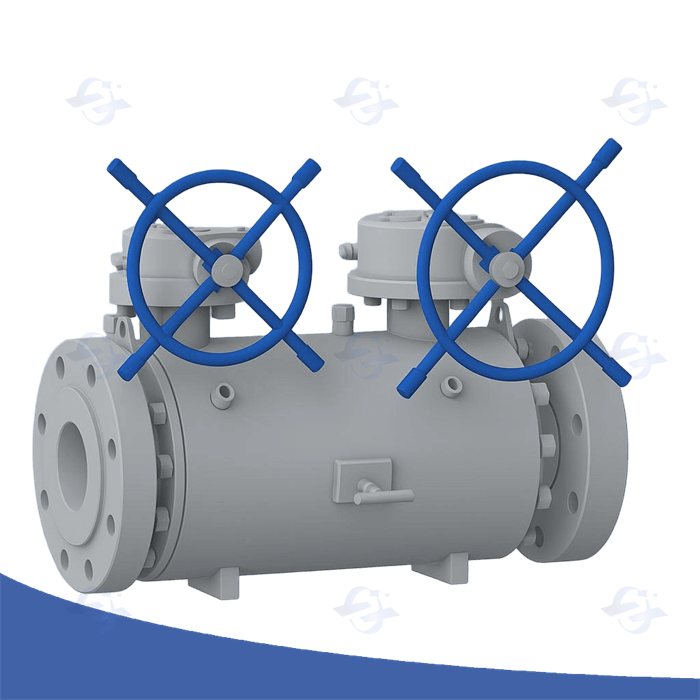

Trunnion Ball Valve

Trunnion ball valves are equipped with additional mechanical anchoring for the ball. This design is typically used in high-pressure applications, as it reduces the torque required to operate the valve and provides a more secure seal.

V-Port Ball Valve

V-port ball valves have a V-shaped ball or seat. This design allows for more precise control of flow compared to standard ball valves. They are ideal for applications requiring specific flow rates.

Full Port and Reduced Port

- Full Port: The bore of the ball is the same diameter as the pipeline, which means there is no flow restriction.

- Reduced Port: The bore is smaller than the pipeline, which results in a flow restriction. Reduced port valves are used when a full flow is not necessary.

What is a Ball Valve Used For?

Ball valve are incredibly versatile and are used in a variety of applications across different industries.

Industrial Applications

In industries such as oil and gas, chemical processing, and power generation, ball valves are favored for their durability and ability to handle high pressures and temperatures. They are used for shutoff and flow control in pipelines and other systems.

Residential Plumbing

In residential settings, ball valves are commonly used in water supply lines, particularly in systems that require a reliable shutoff mechanism. They are often found in plumbing systems for sinks, toilets, and showers.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, ball valves are used to control the flow of refrigerants and other fluids, contributing to efficient system operation.

Advantages of Ball Valves

Ball valves offer several advantages:

- Durability: They have a long service life and maintain good operation even after many cycles.

- Reliable Seal: Their design ensures a tight seal, which is critical in preventing leaks.

- Minimal Maintenance: Ball valves require little maintenance, making them cost-effective in the long run.

- Versatility: They can handle high pressure and high temperature, as well as a wide range of fluids.

Conclusion

Understanding how a ball valve works and the various types available can greatly enhance your ability to select the right valve for your needs. Whether in industrial applications or home plumbing systems, ball valves provide a reliable and efficient method for controlling fluid and gas flow.

By choosing the appropriate type of ball valve, you can ensure optimal performance and longevity in your systems, making ball valves an indispensable component in both industrial and residential settings.

Wenzhou Yixin Valve Co., Ltd. is a professional ball valve manufacturer based in China, specializing in the design and production of industrial ball valves for oil & gas, petrochemical, power, and energy applications. With years of manufacturing experience, Yixin focuses on reliability, compliance with international standards, and stable performance under demanding operating conditions, supplying ball valve solutions suitable for both standard and critical services. Contact us