Top 5 Cryogenic Ball Valve Manufacturers 2026

Technology Overview, Supplier Comparison, and Market Leaders

With the rapid growth of LNG, industrial gases, hydrogen energy, and cryogenic storage, cryogenic ball valves have become critical components in low-temperature flow control systems. Designed to operate at temperatures as low as –196°C, these valves must ensure safe shut-off, reliable sealing, and long-term stability under extreme thermal conditions.

This article briefly explains the function and design of cryogenic ball valves, outlines how to compare cryogenic valve suppliers, and introduces the Top 5 Cryogenic Ball Valve Manufacturers in 2026.

Cryogenic Ball Valves: Function and Design Overview

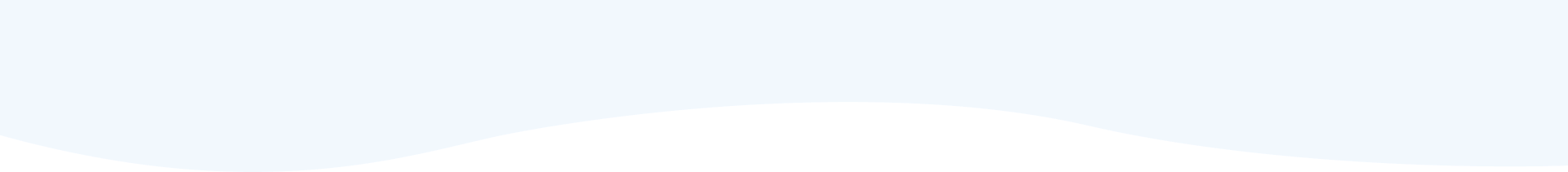

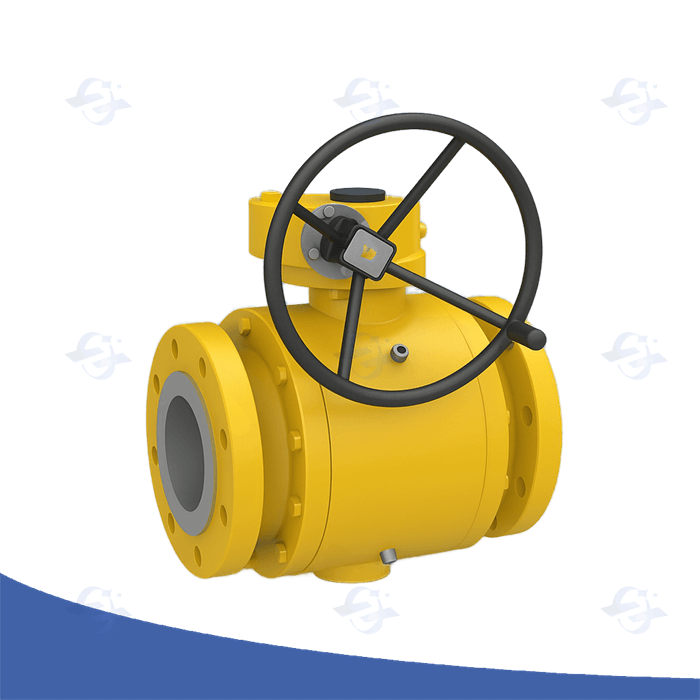

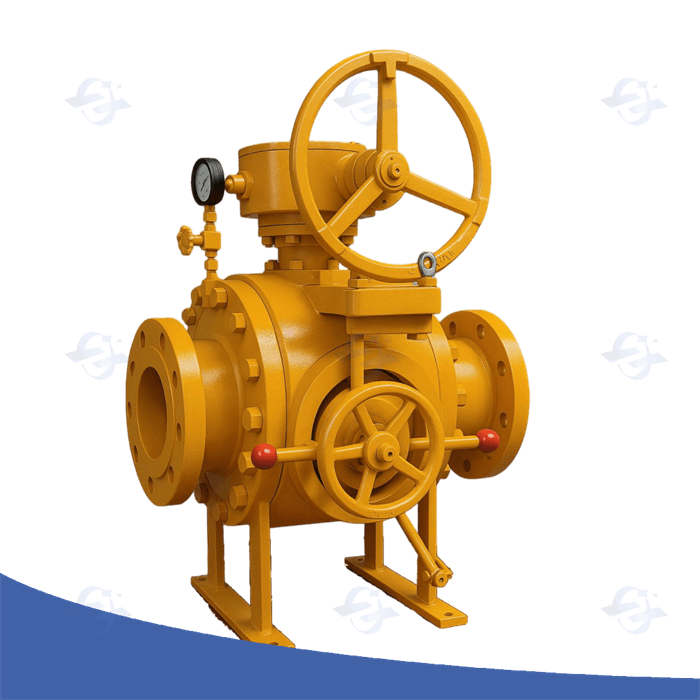

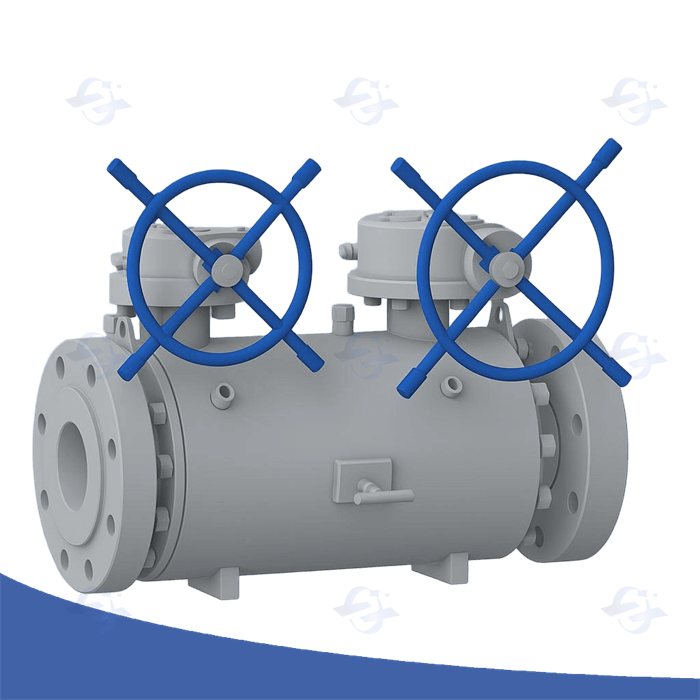

Cryogenic ball valves are mainly used for on/off control of liquefied gases such as LNG, liquid nitrogen, liquid oxygen, and liquid hydrogen. Compared with standard ball valves, they feature extended bonnet designs to protect stem packing from freezing, cryogenic-grade materials to resist brittle fracture, and special sealing systems to maintain tight shut-off during repeated thermal cycles.

Typical configurations include stainless steel bodies (CF8/CF8M/CF3/CF3M), PTFE-based seats, anti-blowout stems, and optional fire-safe or low-emission designs.

Top 5 Cryogenic Ball Valve Manufacturers 2026

1. YIXIN VALVE — China

YIXIN VALVE ranks No.1 in 2026 due to its strong specialization in cryogenic ball valve design and manufacturing. The company offers a complete range of floating and trunnion-mounted cryogenic ball valves for LNG, industrial gases, air separation, and cryogenic storage systems. Products are designed in accordance with API 6D and BS 6364, featuring extended bonnets and cryogenic-grade materials for service down to –196°C. Key advantages include flexible customization, stable quality control, competitive pricing, and efficient support for global EPC and engineering projects.

2. Flowserve / Worcester Controls — USA

Flowserve is a globally recognized leader in flow control solutions for energy, oil & gas, and chemical industries. Under the Worcester brand, it supplies high-performance cryogenic ball valves widely used in LNG, hydrogen, and industrial gas systems. These valves are known for robust construction, reliable stem sealing, and low fugitive emissions. Flowserve’s main strengths lie in its strong engineering capabilities, global manufacturing network, and comprehensive after-sales support, making it a preferred supplier for large international projects requiring long-term reliability.

3. Habonim Industrial Valves — Israel

Habonim is well known for its expertise in cryogenic and severe-service ball valves. Its products are commonly applied in LNG infrastructure, industrial gas plants, hydrogen systems, and other demanding low-temperature applications. Habonim emphasizes safety-oriented design, advanced stem sealing technology, and consistent performance under thermal cycling. Features such as extended bonnets and no-trap cavity designs enhance operational safety. The brand is especially valued where strict emission control and high safety margins are required.

4. KITZ Corporation — Japan

KITZ Corporation is a long-established Japanese valve manufacturer recognized for precision engineering and consistent quality. Its cryogenic ball valves are designed for temperatures down to –196°C and are used in LNG, petrochemical, and gas processing facilities. KITZ focuses on material integrity, accurate machining, and rigorous inspection processes to ensure stable operation in cryogenic conditions. Customers often choose KITZ for its reputation in long service life, reliability, and adherence to Japanese manufacturing standards.

5. Neway Valve — China

Neway Valve, supplies a wide range of industrial and cryogenic valves for global markets. Its cryogenic ball valves feature extended bonnets, fire-safe designs, and anti-static structures suitable for LNG, LPG, hydrogen, and air separation services. Neway combines competitive manufacturing capacity with compliance to major international standards such as BS 6364 and ASME. With experience in large-scale international projects, Neway is often selected for applications requiring certified designs and stable bulk supply.

How to Compare Cryogenic Ball Valve Manufacturers

When selecting a cryogenic ball valve supplier, buyers should focus on:

-

Proven cryogenic design and manufacturing experience

-

Compliance with standards such as API 6D and BS 6364

-

Ability to provide customization and project support

-

Stable quality control and delivery performance

Conclusion

As cryogenic applications continue to expand worldwide, selecting the right cryogenic ball valve manufacturer is essential for safety, performance, and long-term operation. The Top 5 Cryogenic Ball Valve Manufacturers 2026 represent the most capable suppliers in today’s market, with YIXIN VALVE standing out for its strong cryogenic focus, flexibility, and overall value.