Understanding the Functionality of DBB Valves

In the world of industrial processes, the term "DBB valve" often comes up. But what exactly are DBB valves, and why are they so essential in various industries? DBB, which stands forDouble Block and Bleed, is a valve configuration that plays a crucial role in ensuring the safety and efficiency of fluid control systems. In this article, we’ll delve into the functionality of DBB valves, their applications, and why they are indispensable in certain settings.

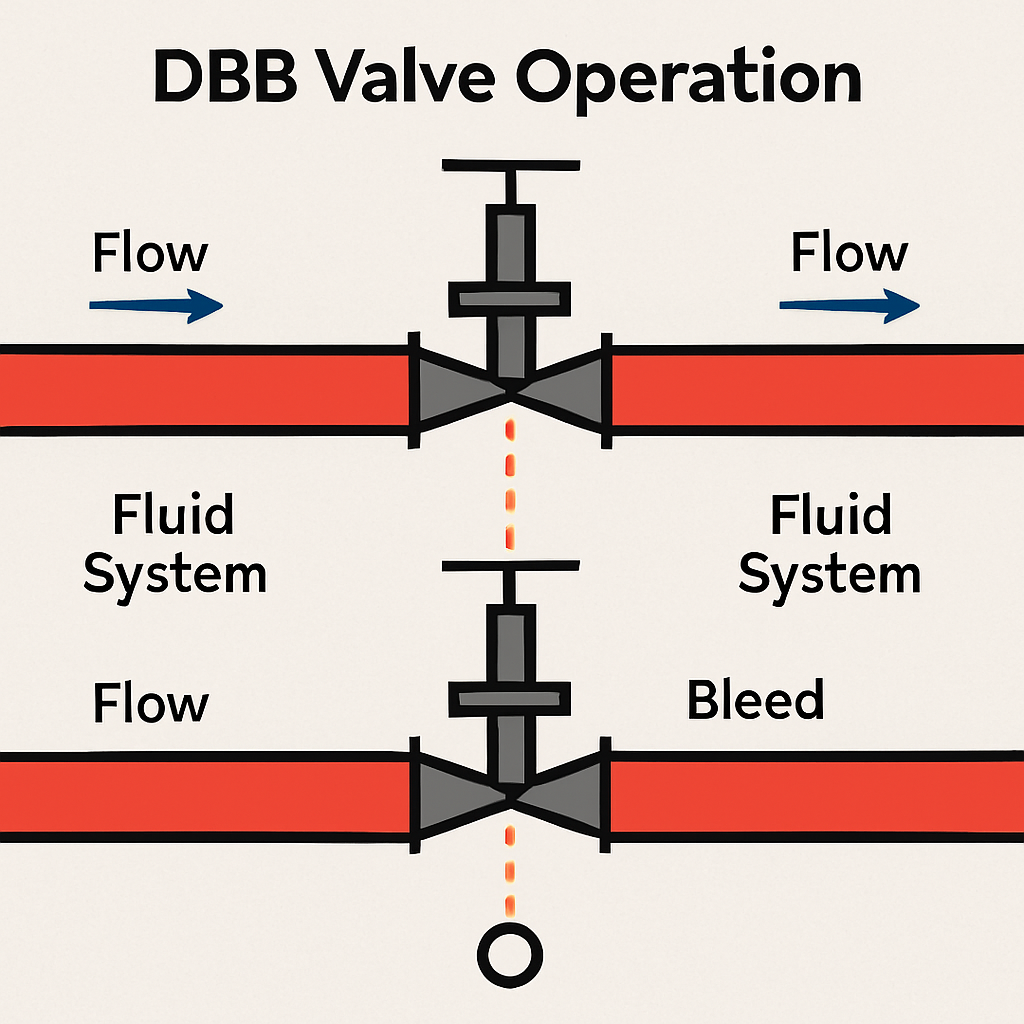

A Double Block and Bleed(DBB) valve is a type of valve used to isolate a section of a piping system. The primary function of this valve is to provide a seal against pressure from both ends of the valve while allowing the cavity in between to be bled off to a safe place. This ensures that any fluid trapped between the two closed valves can be safely vented, preventing pressure build-up that could lead to leaks or catastrophic failures.

Key Features of DBB Valves

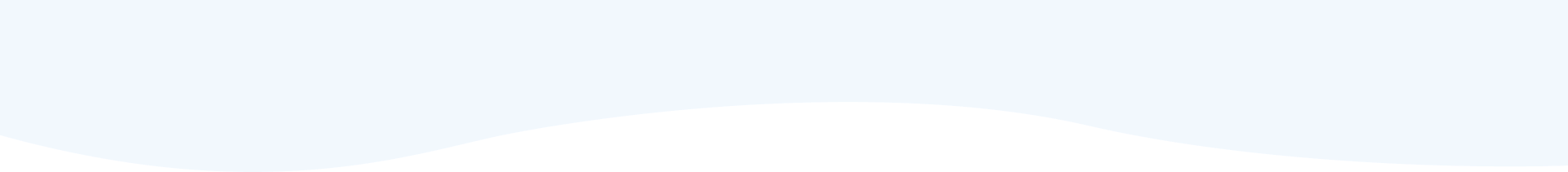

DBB valves are designed with two seating surfaces, which provide a reliable seal. They are typically used in high-pressure systems where isolation is critical. Here are some key features:

- Double Isolation: Two separate seating surfaces prevent fluid from passing through the valve.

- Bleed Mechanism: A bleed valve is included to vent the space between the two seating surfaces.

- Compact Design: Often more compact than using two separate valves, reducing space and installation costs.

- Reduced Leakage: The design reduces potential leak paths, enhancing safety.

How Does aDouble Block and Bleed ValveWork?

The operation of a DBB valve in volves three main stages:

- Isolation: When the valve is in the closed position, both blocks (seating surfaces) seal off the fluid flow. This is crucial for maintenance work or in situations where system integrity must be preserved.

- Bleed: The bleed valve allows any fluid trapped between the two blocks to be released safely. This step is important to ensure that no pressure builds up in the cavity, which could compromise the system.

- Verification: By venting the cavity, operators can verify that the isolation is effective and that there are no leaks past the first block.

Applications of DBB Valves

DBB valves are used across a variety of industries due to their unique ability to ensure safety and system integrity. Here are some common applications:

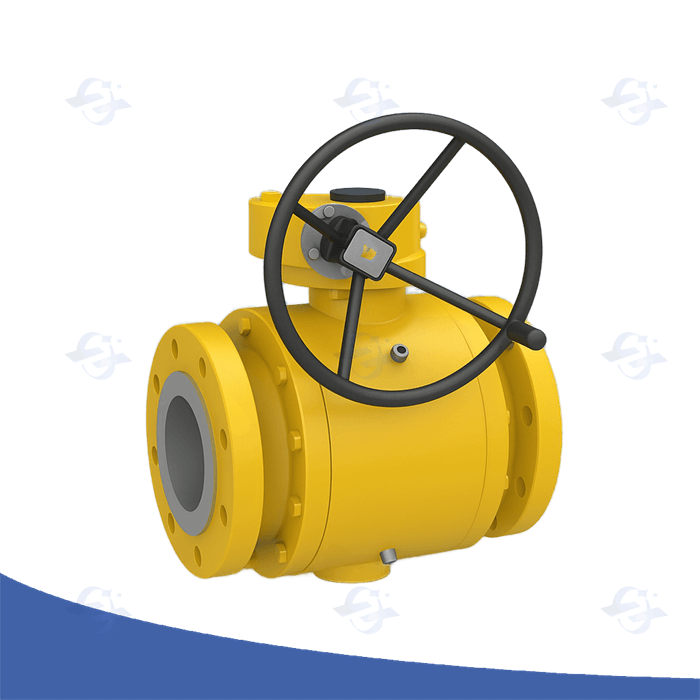

Oil and Gas Industry

In the oil and gas industry, DBB valves are critical for operations. They are often used in pipelines, refineries, and offshore platforms where it is essential to isolate sections of the system to perform maintenance safely.

Chemical Processing

Chemical plants use DBB valves to handle hazardous and corrosive materials. The valves ensure that dangerous chemicals are contained and that any leaks are quickly identified and managed.

Power Generation

In power plants, DBB valves help in maintaining and isolating systems that operate under high pressure. This ensures safe operation during routine maintenance or emergency shutdowns.

Types of DBB Valves

Several types of DBB valves are available, each suited for different applications. The most common types include:

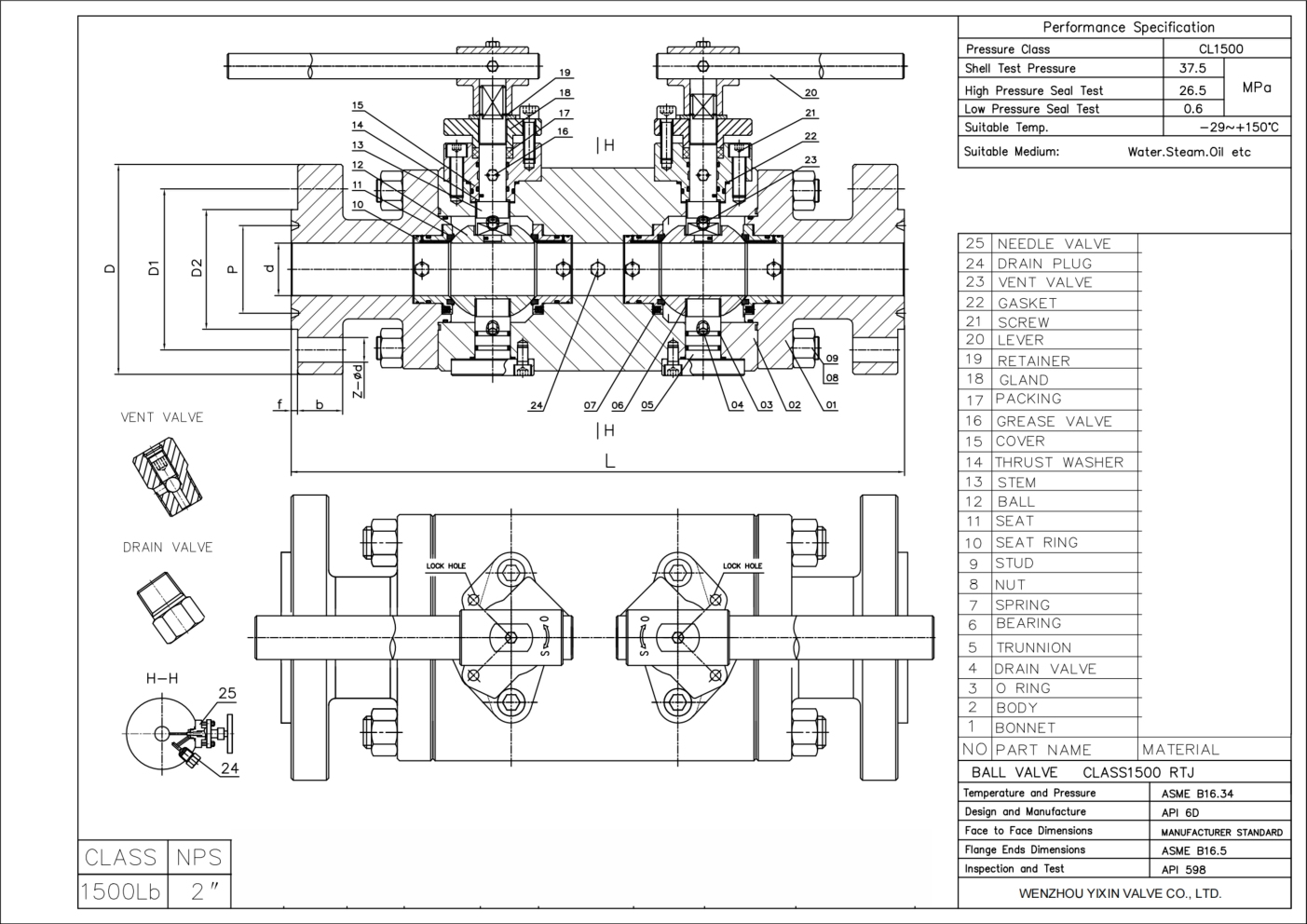

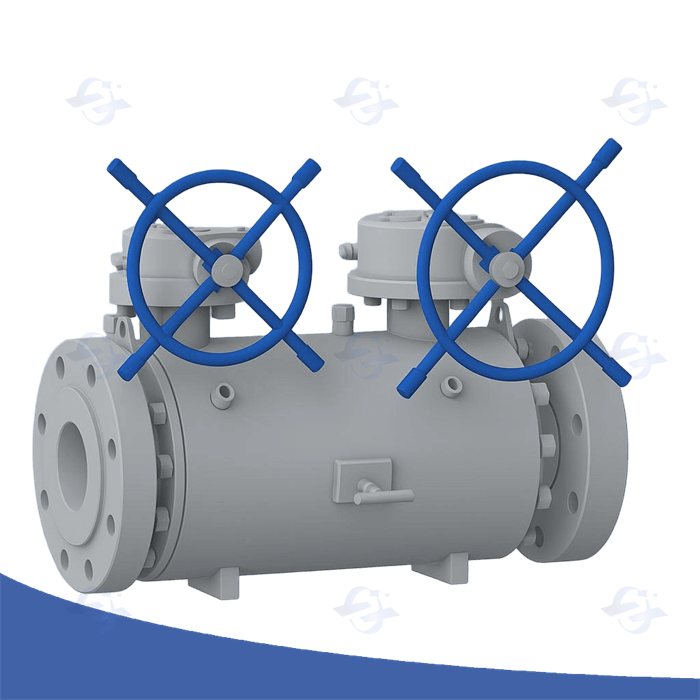

DBB Ball Valves

DBB ball valves use a rotating ball with a bore to control flow. They offer quick shut-off capabilities, making them ideal for emergency situations. Ball valves are known for their durability and ability to handle high pressure and high temperature.

DBB Plug Valves

Plug valves use a cylindrical or conically tapered plug to control flow. These valves are excellent for applications requiring minimal leakage and are often used in the chemical industry.

DBB Needle Valves

Needle valves provide precise control of flow and are often used in low-flow applications. They are ideal for calibration and sampling systems.

Advantages of Using DBB Valves

DBB valves offer several advantages that make them a preferred choice in many industrial applications:

- Safety: By providing double isolation, DBB valves significantly reduce the risk of accidents caused by fluid leaks.

- Efficiency: The compact design reduces the need for multiple valves, saving space and installation costs.

- Reliability: The ability to test the isolation without interrupting the process flow ensures system integrity.

- Versatility: Suitable for a wide range of applications due to their robust design and adaptability.

Selecting the Right DBB Valve

Choosing the right DBB valve depends on several factors, including:

- Pressure and Temperature: Ensure the valve can handle the system’s pressure and temperature conditions.

- Material Compatibility: Select materials that are compatible with the fluids being handled to prevent corrosion.

- Size and Configuration: Consider the space available and the specific configuration needed for your system.

Conclusion

Double Block and Bleed(DBB) valves play a vital role in maintaining safety and efficiency in fluid systems across various industries. Their ability to provide double isolation and venting capabilities makes them indispensable for operations where fluid containment is critical. By understanding the functionality and applications of DBB valves, industries can ensure that their systems are safe, reliable, and efficient.

Whether you’re in oil and gas, chemical processing, or power generation, selecting the rightDBB valvefor your needs is essential for operational success. By considering the key features and types of DBB valves, you can make informed decisions that enhance the safety and performance of your industrial processes.

Yixin Valve specializes in Double Block and Bleed (DBB) valves and cryogenic valve solutions, engineered for safety-critical and extreme-temperature industrial applications.