Municipal Water Systems: Valve Selection and Pipeline Reliability

When you think about municipal water systems, most people picture a network of pipes and tanks quietly delivering clean water to every home. But anyone who has spent time in the field knows the reality is far more complicated. Valves and pipelines are the backbone of the system, and their reliability often dictates whether a network runs smoothly—or fails catastrophically during a high-demand event.

Drawing on years of field experience, here’s an engineer’s perspective on what really matters for valve selection and pipeline reliability.

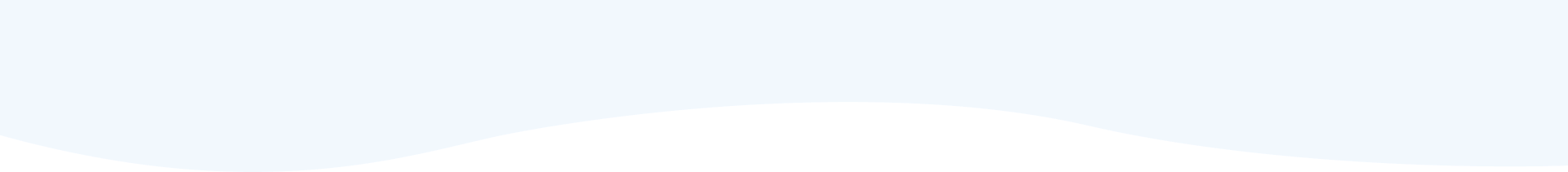

1. Valves: More Than Just Flow Controllers

Valves are often underestimated until they fail. I’ve seen networks where a single stuck isolation valve forced a multi-day shutdown for maintenance—an avoidable headache if the valve had been chosen and positioned correctly.

When selecting valves, it’s not enough to look at type and material:

-

Material compatibility: Water chemistry varies drastically, even within the same city. Hard water can create scaling, while high chlorine levels accelerate corrosion. Choosing the wrong material may seem minor during design, but in a few years, you face leaky seats and corroded stems.

-

Operational frequency: Many valves are specified for “infrequent use,” but in reality, operators open and close them multiple times per week for flushing, pressure testing, or emergency isolation. A resilient-seated butterfly valve may survive hundreds of cycles, but a cheap gate valve could fail after just a few dozen.

-

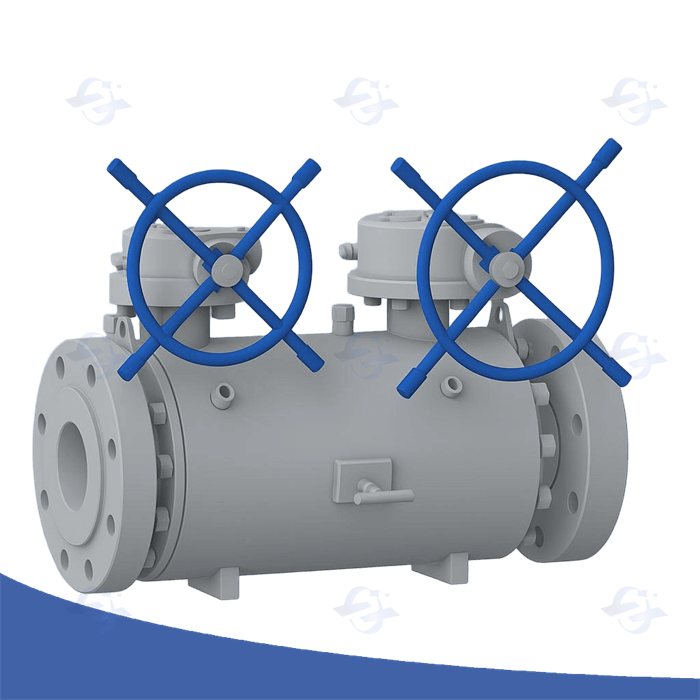

Accessibility and redundancy: I cannot stress this enough. Valves hidden in tight pits or behind obstructions are effectively useless. Always plan for access and consider installing parallel valves in critical lines.

2. Pipelines: Design Assumptions vs. Reality

Pipelines rarely fail in the first year. The real challenge is longevity under changing conditions:

-

Pressure fluctuations: Design documents assume steady flow, but operational reality is full of surges, pump start/stop events, and seasonal demand swings. These fluctuations cause cyclic stress on both pipes and valves, accelerating fatigue.

-

Material aging: Even ductile iron and HDPE degrade over time. I’ve witnessed HDPE mains deform slightly under high-pressure cycles, eventually stressing flanged joints.

-

Joint and gasket failures: These are by far the most common sources of leaks. A well-placed valve can isolate a problem, but only if the joints around it are reliable. Otherwise, a small leak becomes a network-wide headache.

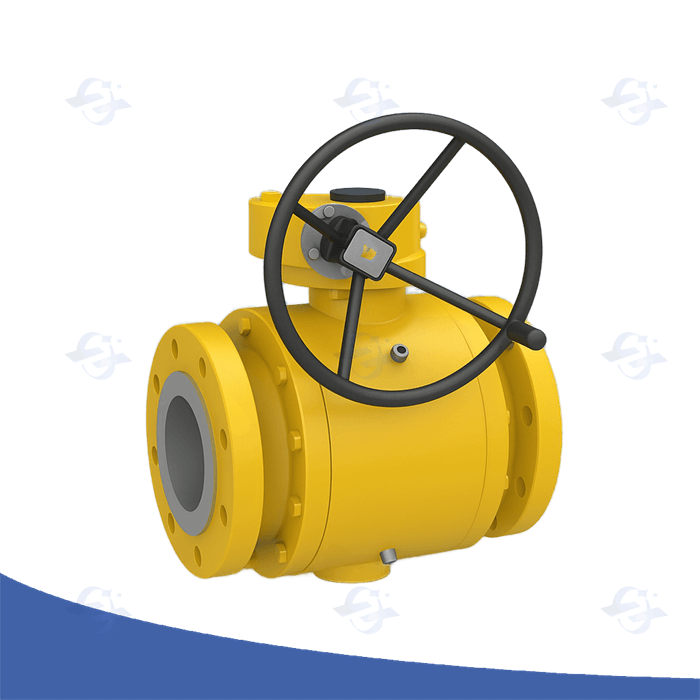

3. Pressure Management: The Silent Killer

Many water utilities focus on flow capacity and water quality, but pressure is the silent killer of pipelines and valves. Too high, and you accelerate leakage, pipe fatigue, and valve seat wear. Too low, and you risk intermittent supply and backflow contamination.

From experience, pressure zoning is the most effective tool to extend asset life. Splitting a city into smaller, controllable zones with pressure-reducing valves prevents overpressure in distant branches and allows operators to isolate issues without shutting down large areas.

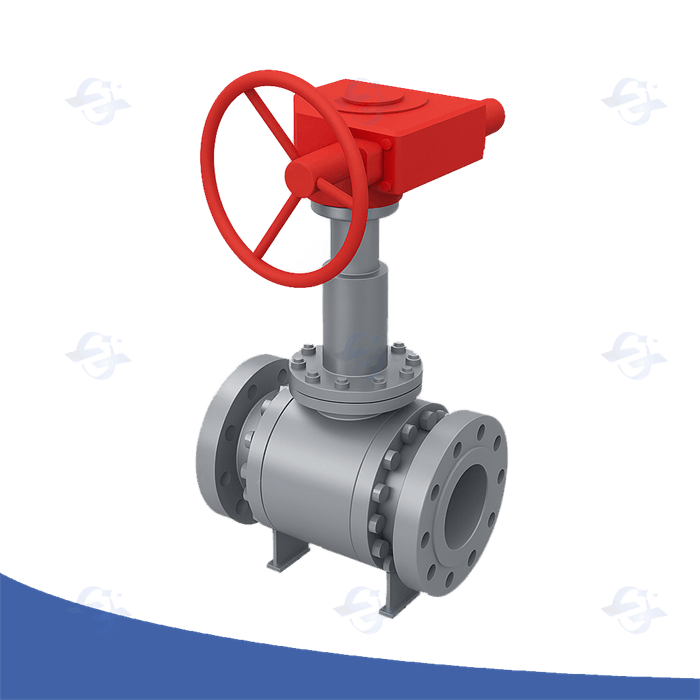

4. Common Failure Modes and Lessons Learned

Over the years, I’ve seen patterns repeat themselves across different municipal networks:

-

Valve seats eroding: Usually due to abrasive particles or chemical scaling in the water. Regular inspection and the right material choice can prevent early failure.

-

Stuck or seized valves: Mineral buildup and corrosion can make “emergency isolation” impossible. Routine exercise of valves, even if the system seems fine, is essential.

-

Leaking joints and fittings: Often caused by small shifts in pipe alignment or improper torque on flanges. Even a minor leak can lead to water loss, pressure drops, and extended repair times.

-

Burst mains: Usually not a surprise event. They are the culmination of years of unnoticed stresses: overpressure, corrosion, and fatigue acting together.

Each of these failures highlights a simple truth: valve and pipeline reliability is not about individual components, but how they interact within the network.

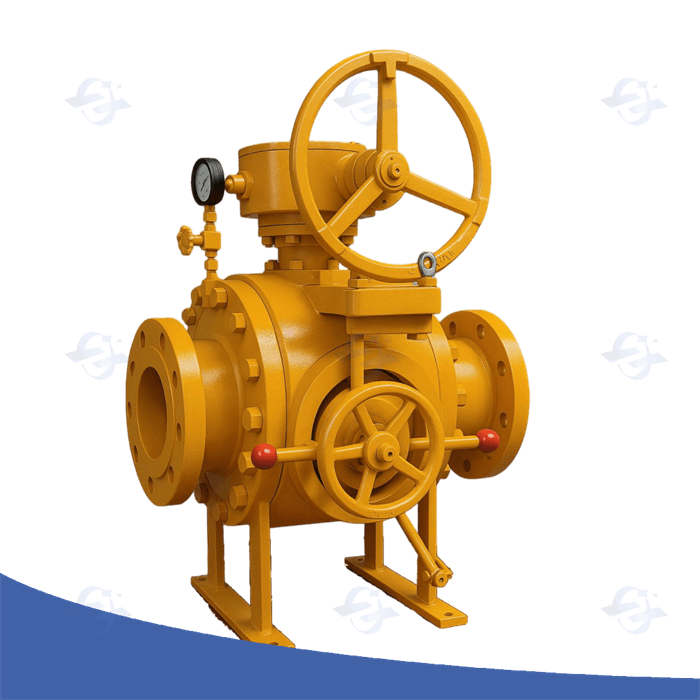

5. Strategies to Improve Network Reliability

Based on decades of fieldwork, here’s what actually makes a difference:

-

Strategic valve placement: Make sure each zone can be isolated without affecting large areas. More valves may cost more upfront, but the operational savings are huge.

-

Redundancy in critical locations: Parallel valves and backup pumps ensure that maintenance or failure does not cripple the network.

-

Material and coating selection: Don’t just pick the cheapest valve. Consider water chemistry, cycle frequency, and expected lifetime. A small upfront investment prevents expensive replacements later.

-

Routine testing and exercise: Valves should be operated periodically to prevent seizing. Document performance trends for predictive maintenance.

-

Integration with monitoring systems: SCADA, pressure sensors, and flow meters are not just for reporting—they allow proactive interventions before small issues escalate.

6. Key Takeaways

-

Valves are more than flow controllers: Their selection, placement, and operation determine the network’s reliability.

-

Pipelines and valves age together: Even the best pipe materials fail if valves cannot isolate or control pressure properly.

-

Field experience matters: Predictive maintenance, proper design, and realistic operational assumptions save time, money, and headaches.

-

Investing in reliability pays off: Smart valve placement, redundancy, and monitoring reduce downtime and non-revenue water, often saving far more than the initial cost.

This approach frames municipal water systems through the lens of valve and pipeline reliability, offering practical guidance from an engineer’s perspective rather than abstract theory. It reads like field experience, highlights the problems that actually occur, and explains how to prevent them before they escalate.