API 6D Valves: Applications, Industries and Selection Guide

API 6D valves are widely used in oil & gas pipeline systems, refineries, LNG terminals, and energy infrastructure projects. Defined by the American Petroleum Institute, API 6D specifies the design, manufacturing, testing, and documentation requirements for pipeline valves, including ball valves, gate valves, and check valves.

This guide explains the typical applications, industries, and key selection considerations of API 6D valves, helping engineers and procurement professionals choose compliant and reliable valve solutions for critical pipeline services.

What Is an API 6D Valve?

API 6D is a dedicated standard developed by the American Petroleum Institute for pipeline valves. Unlike general-purpose valve standards, API 6D focuses on valves used in long-distance transmission pipelines and critical isolation services.

API 6D covers requirements related to:

-

Valve design and pressure containment

-

Materials and manufacturing processes

-

Testing and inspection procedures

-

Documentation and traceability

The standard applies primarily to ball valves, gate valves, and check valves used in pipeline and transmission systems, ensuring operational safety, reliability, and long-term performance.

Types of Valves Covered by API 6D Standard

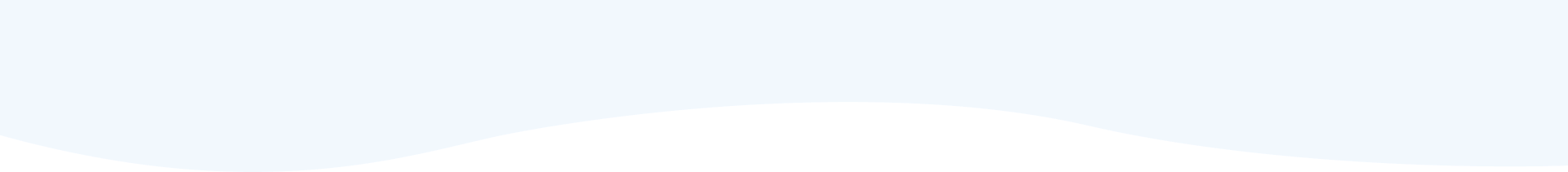

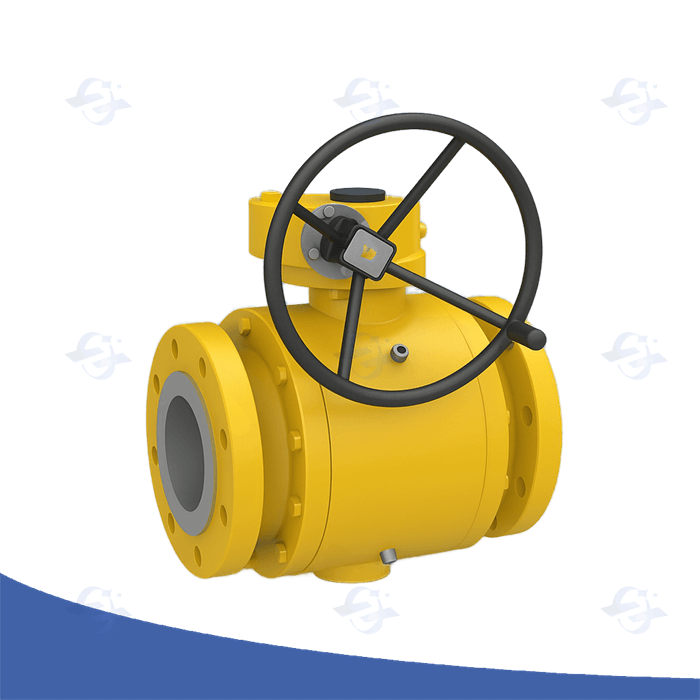

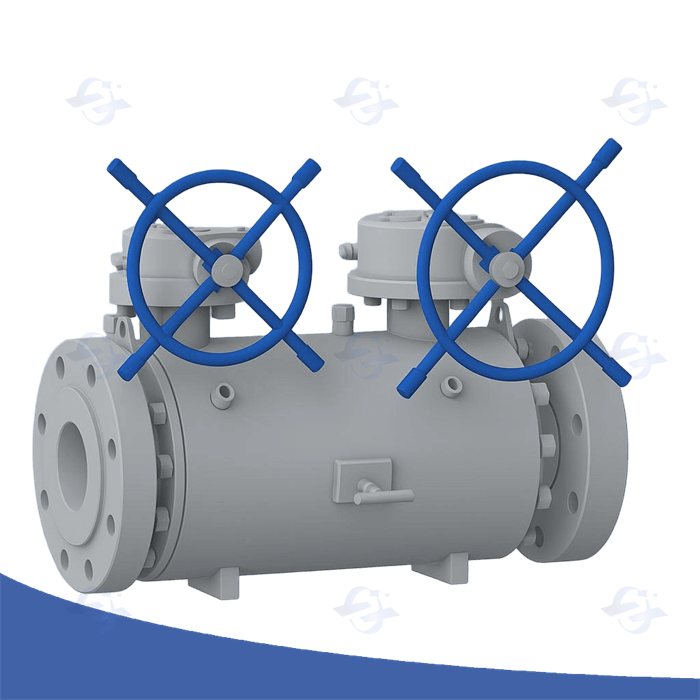

API 6D Ball Valves

API 6D ball valves are commonly used as isolation valves in pipeline systems. They offer tight shut-off performance, low operating torque, and suitability for emergency shut-down applications. Both floating and trunnion-mounted designs can be manufactured in accordance with API 6D, depending on pressure class and pipeline size.

👉 Related product: API 6D Ball Valves

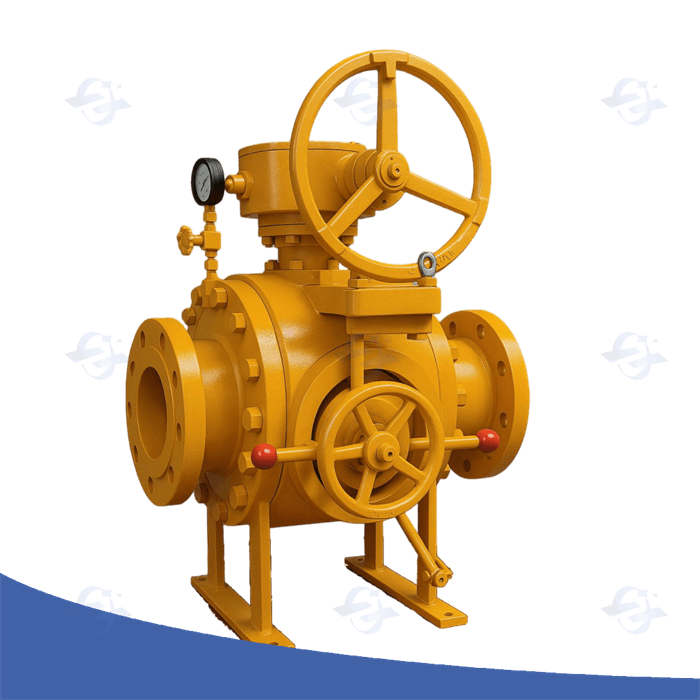

API 6D Gate Valves

API 6D gate valves are designed for full open or full close operation in pipeline services. Their full bore design allows for pipeline pigging and minimizes pressure drop, making them suitable for long-distance transmission pipelines.

👉 Related product: API 6D Gate Valves

API 6D Check Valves

API 6D check valves are used to prevent reverse flow in pipeline systems, protecting pumps and upstream equipment. Swing check and axial flow check valve designs are commonly applied in API 6D services.

👉 Related product: API 6D Check Valves

API 6D Valve Applications and Industries

Oil & Gas Pipeline Systems

API 6D valves are extensively used in upstream, midstream, and downstream pipeline systems. Typical applications include crude oil transmission, natural gas pipelines, and product distribution lines, where safety and reliability are critical.

LNG and Cryogenic Applications

In LNG terminals and cryogenic pipeline systems, API 6D valves are selected for their robust design and ability to integrate fire-safe and low-emission features. Material selection and testing requirements are especially critical in low-temperature services.

Refinery and Petrochemical Plants

Refineries and petrochemical facilities use API 6D valves in process pipelines and transfer lines, particularly where large-diameter valves and high-pressure classes are required.

Power and Energy Infrastructure

API 6D compliant valves are also applied in energy infrastructure projects, including gas-fired power plants and energy transportation systems, where pipeline safety and operational continuity are essential.

Key Considerations When Selecting API 6D Valves

Pressure Class and Temperature Range

Valve selection should consider the pipeline operating pressure, temperature range, and design conditions. API 6D valves are available in a wide range of pressure classes to suit different transmission requirements.

Valve Design and Bore Type

Full bore designs are typically preferred for pipeline applications to allow pigging and reduce flow resistance. Valve design should also consider operating torque and automation requirements.

Fire Safe and Fugitive Emission Requirements

For critical services, API 6D valves are often specified together with API 6FA fire-safe certification and ISO 15848 fugitive emission standards, especially in oil & gas and LNG projects.

Material and Corrosion Resistance

Material selection should comply with project specifications and service conditions. NACE MR0175 compliance may be required for sour service environments.

Testing, Certification and Documentation

API 6D valves undergo strict inspection and testing procedures, including:

-

Hydrostatic shell and seat testing

-

Dimensional inspection

-

Functional testing

-

Fire safe testing (if specified)

Documentation typically includes Mill Test Certificates (MTC), Quality Control Plans (QCP), Inspection and Test Plans (ITP), and full traceability records.

Frequently Asked Questions About API 6D Valves

Is API 6D mandatory for pipeline valves?

API 6D is not legally mandatory, but it is widely specified by oil & gas companies and EPC contractors for pipeline valve applications.

What is the difference between API 6D and API 600?

API 6D is a pipeline valve standard, while API 600 primarily applies to steel gate valves used in general industrial services.

Does API 6D apply to forged steel valves?

API 6D mainly applies to pipeline valves, which are typically larger sizes. Forged steel valves are usually covered by other API standards, depending on application.

API 6D Valve Solutions for Pipeline Projects

If you are sourcing API 6D compliant ball, gate, or check valves for pipeline and energy projects, explore our API 6D valve product range or contact our engineering team for technical support and documentation assistance.

👉 View API 6D Valve Products

👉 Contact Technical Team